A diverse range of lashing components are at hand to secure containers. P&I clubs have long favored a setup incorporating twistlocks, lashing rods, turnbuckles, and lashing plates. Refer to the table for typical component placements.

Fixed equipment

attached to ship

-

Fixed lashing equipment welded to the ship's deck, including raised deck sockets, dovetail sockets, flush sockets, elephant foot sockets, lashing plates, or D-rings.

-

Crucial for providing stable anchor points during transportation, ensuring cargo safety and integrity.

-

Used alongside various twistlock types to secure containers, vehicles, and cargo.

-

Designed to withstand transit forces for reliable cargo securing.

-

Helps meet industry standards and regulations for cargo transportation safety.

RAISED SOCKETS

Raised ISO deck sockets on the vessel's deck secure twistlocks and stacking cones, accommodating different types and offering customizable height options.

Flush sockets

Positioning twistlocks or stacking cones in the cargo hold using weldable sockets for container lashing. Sockets weld to the deck, ensuring watertightness, and are available in various configurations.

D rings

An additional anchoring location for a turnbuckle. D-ring and weldable strap sets with breaking loads from 4t to 50t. Strap welds to the deck while D-ring remains movable. Compatible with lashing chains or webbing straps for cargo securing.

LASHING PLATES

Fixed lashing point for container securing, welded on deck for in-plane use with lashing bars and turnbuckles. Available in single, double, triple, and quadruple configurations. Turnbuckle end secured to the plate and container corner hole.

LASHING POTS

Flush lashing socket welded to the vessel deck for Ro-Ro securing with chains or webbing straps. Also used for trailers and cars, with a breaking load of up to 36t.

dovetails foundation

Dovetail (U-frame) socket, welded to vessel deck, for securing container corner castings with dovetail twistlocks. Available in 45º and 55º angles, single or double, with customizable CC distances. Standard separations: 203mm and 258mm, breaking load: 42t.

WELDABLE CONES

Used to prevent horizontal movement of 20-foot containers in 40-foot cell guides. Often found at the base of a cell guide.

Breech base foundation

Dovetail (U-frame) socket, welded to vessel deck, for securing container corner castings with dovetail twistlocks. Available in 45º and 55º angles, single or double, with customizable CC distances. Standard separations: 203mm and 258mm, breaking load: 42t.

Loose Fittings

adjustable and removable

-

Includes removable components such as twistlocks, cones, stackers, bridge fittings, lashing bars, turnbuckles, base fittings, and others.

-

Adjustable and removable loose equipment offers flexibility in cargo securing arrangements.

-

Customization of the lashing system is based on the unique characteristics of each load.

-

Versatility and efficiency in the transportation process are provided by loose equipment.

-

Loose equipment is combined with fixed equipment for container and cargo securing purposes.

-

These components are vital for adapting to various cargo sizes, shapes, and transportation needs.

-

Tailored and adaptable cargo securing solutions are achieved through the use of loose equipment.

-

Proper inspection, maintenance, and adherence to safety regulations are crucial for ensuring the secure transportation of cargo.

Loose Fittings in Common Use

LASHING BARS

Diagonal lashing bar, used with turnbuckle, supports container stacks on deck, resisting tensile loads. Secured in corner casting front holes. Various lengths available.

turnbuckles

The turnbuckle tightens the lashing rod to a plate or D-ring, resisting tension loads to keep the lashing tight. Regularly grease threads and ensure the locking nut or tab is secure.

Stacking cones

Placed between stacked containers, it slots into corner castings to resist horizontal forces. Various types are available and may be locked into bottom corner castings before lifting a container onboard.

MANUAL Twistlock

Standard intermediate twistlock for container use, resisting horizontal and separation forces. Requires post-fitting locking. Offers left and right locking options. Avoid mixing types to prevent confusion between open and locked positions.

SEMI-AUTOMATIC TWISTLOCK

Semiautomatic twistlock secures containers, resisting forces. Can be installed onshore. Automatically locks into lower container when placed above, unlocked manually or with an actuator pole.

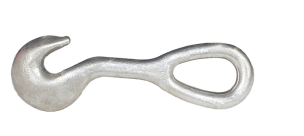

EXTENSION ROD EYE-HOOK

Extension rod extends lashing rod for securing "high cube" containers, fitted at base and connected to turnbuckle.

BRIDGE FITTINGS

Bridge fittings connect top containers of adjacent stacks, usable on deck or in holds. Resistant to tension and compression, they accommodate varying container separations and are tightened using a central nut.

MIDLOCK

Midlock, placed between containers, used with semiautomatic twistlocks on deck. Resists horizontal and separation forces. Fitted ashore, automatically locks into lower container onboard.

PLease also Check THESE Other Lashing components