Stowage and Securing

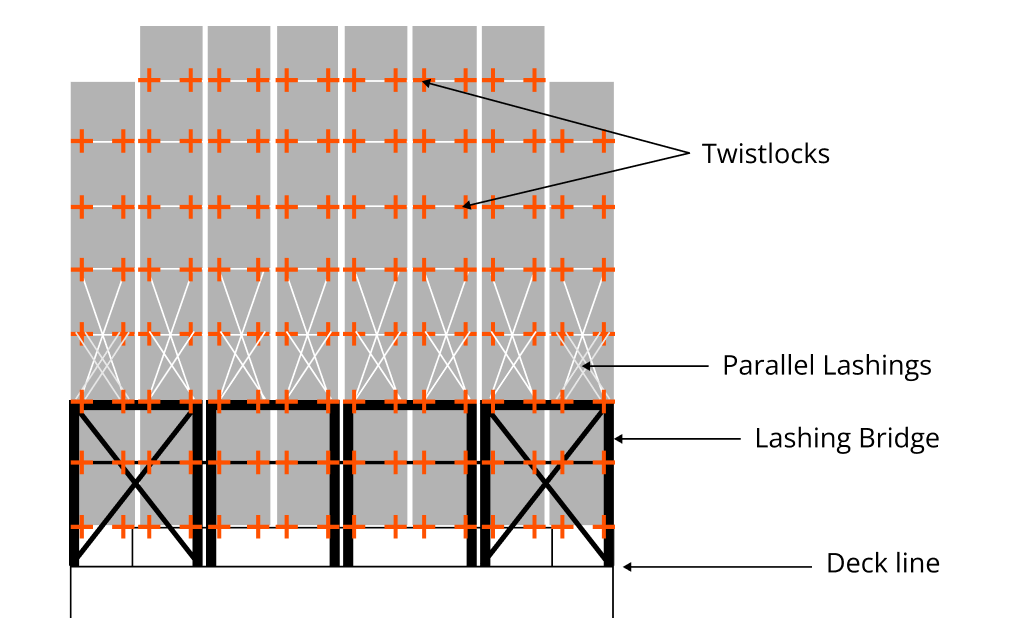

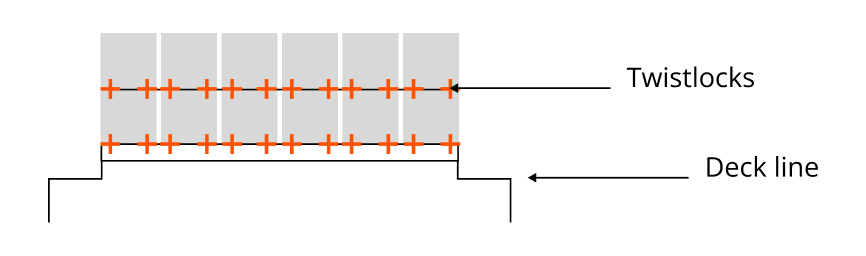

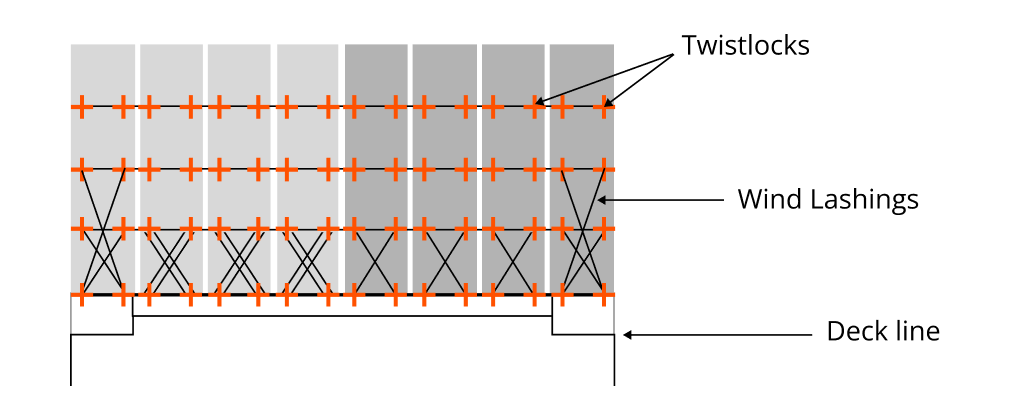

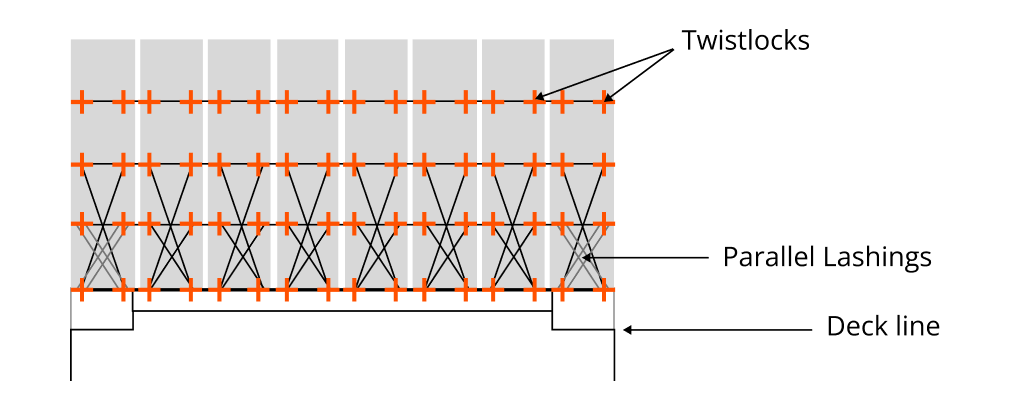

Containers, rectangular in shape, are easily stowed in block arrangements both on and below the deck of ships. On-deck carriage requires ship approval and the use of twistlocks and lashings for securing, typically made of steel rods and turnbuckles.

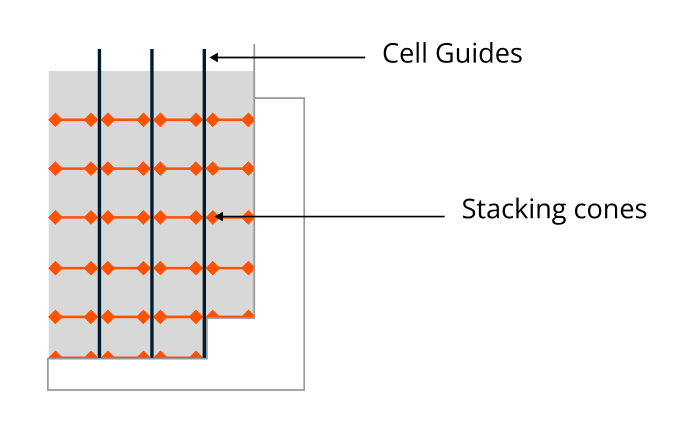

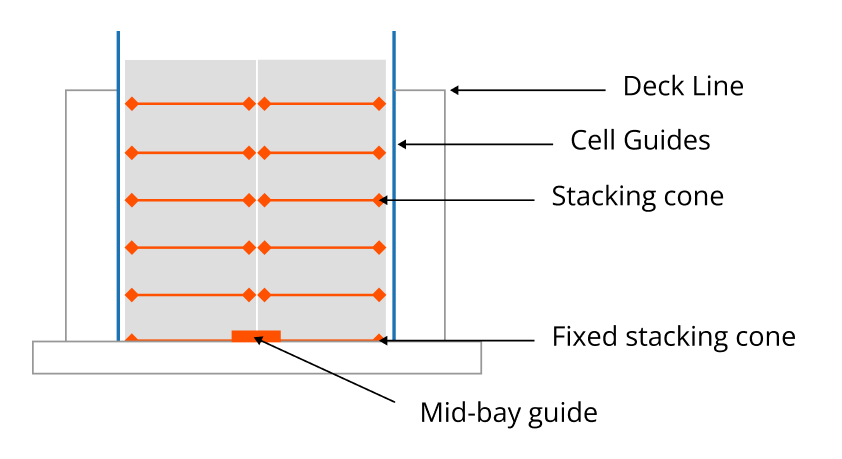

Below-deck carriage involves slotting containers into cell guides on cellular container ships or onto the tank top in dry cargo ships’ holds, secured with stacking cones or buttresses, particularly in holds with side hopper tanks.

For stows exceeding three containers high, lashing rods provide additional strength, complementing twistlocks. Initially, lashings were vertically arranged to resist tipping but are now typically placed diagonally to work in tandem with containers to resist racking.

Twistlocks, designed with vertical and horizontal gaps, are utilized for securing containers, with lashings tightening first during ship motion before twistlocks engage. Proper condition and application of lashing rods are crucial for effective securing during ship movements.

Parallel Lashings

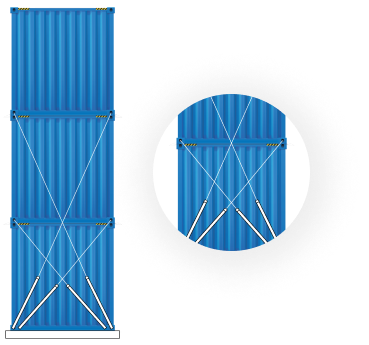

Upper and Lower Crossed Lashing Rods

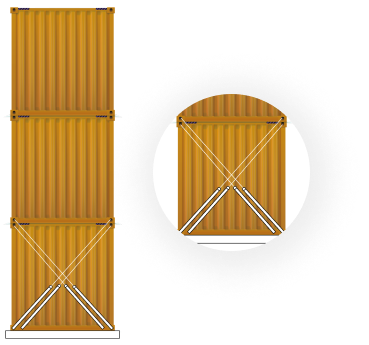

Parallel Lashing Rods

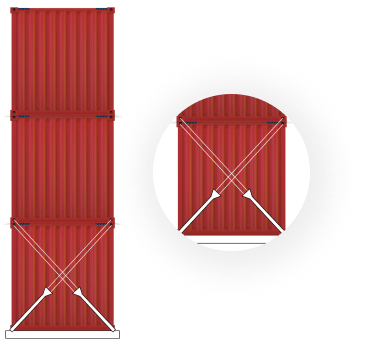

Parallel Lashing Rods with Equalizing Device

A second set of lashings can be installed to reach the bottom of the third tier of containers, as shown in the diagram. Parallel lashings may provide additional strength, arranged one at the top of the first tier and one at the bottom of the second tier.

Their effectiveness is typically 1.5 times that of a single lashing, doubling if a load-equalizing device is used. Bridge fittings, although not commonly used for ease of loading and unloading, are occasionally employed for isolated stacks or in dry cargo ship holds.

The ship’s cargo-securing manual outlines container stowage methods and any weight or strength limits. Common mistakes include exceeding stack weight limits, incorrect lashing application, and placing heavy containers on top.

Their effectiveness is typically 1.5 times that of a single lashing, doubling if a load-equalizing device is used

BELLOW DECK CONTAINER HANDLING

CELL GUIDES VS. WITHOUT

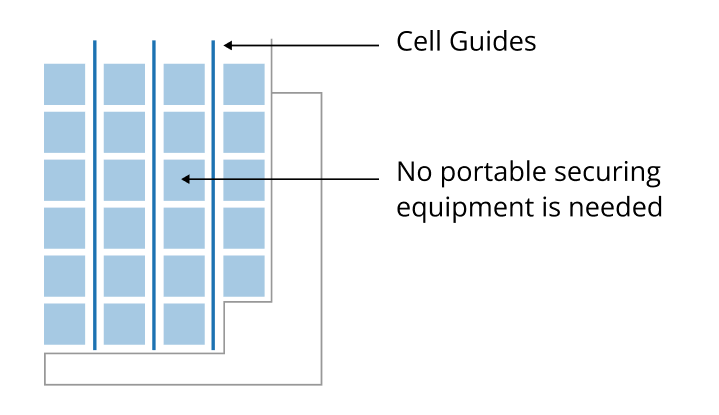

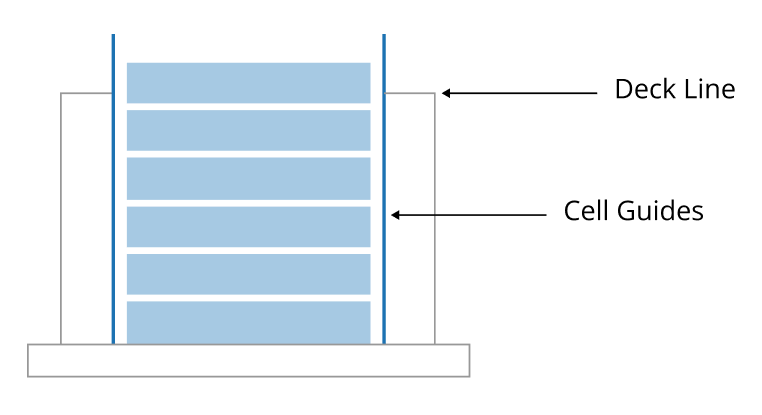

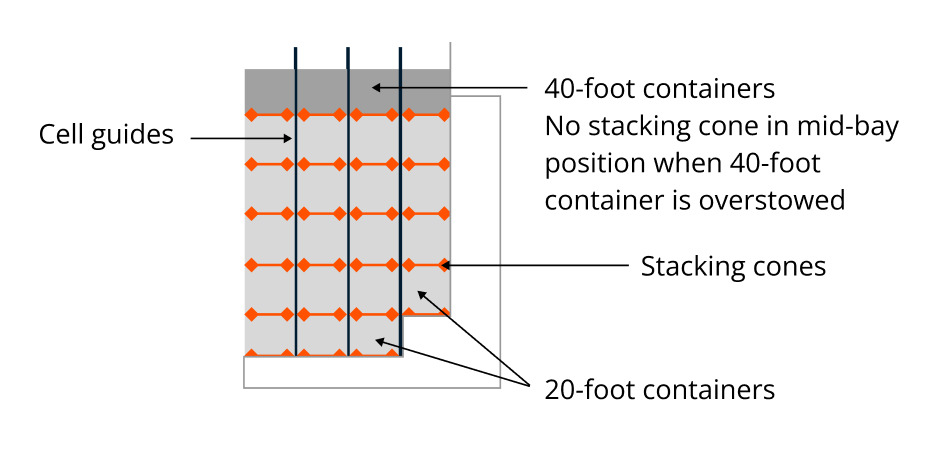

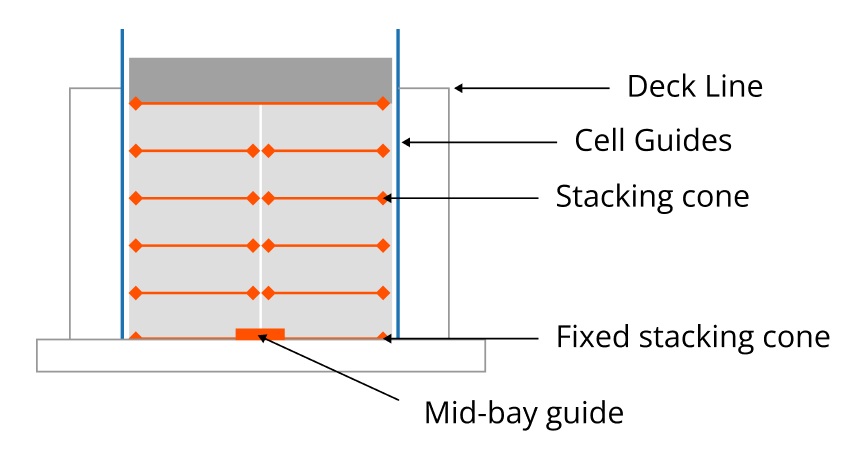

Most container ships’ holds are tailored for 40-foot containers, anchored by vertical steel angle bars, or cell guides, ensuring precise positioning. These guides offer ample longitudinal and transverse support, negating the need for additional securing. Meanwhile, stacking 20-foot containers in 40-foot bays demands longitudinal and transverse reinforcement, achieved through mid-bay guides, stacking cones, and possibly overstowing. It’s vital to inspect guides for deformities before loading.

In contrast, containers without cell guides are secured using locking devices or a combination of locking devices, buttresses, shores, or lashings, aiming to restrain them at their corners. Twistlocks are effective in preventing corner separation. In bulk carriers or general cargo ships, base containers are secured with twistlocks or cones, buttressed for lateral support, and on platforms with cone or twistlock sockets. Achieving a tight block is crucial, ensuring horizontal stability during loading amid ship rolls.

Typical Arrangements for containers stowed below deck:

1

40-FOOT CONTAINERS IN 40-FOOT CELL GUIDES

2

20-FOOT CONTAINERS IN 40-FOOT CELL GUIDES

3

20-FOOT CONTAINERS IN 40-FOOT CELL GUIDES WITH 40-FOOT CONTAINERS STOWED ABOVE

CONTAINERS CARRIED ON DECK

Most container ships’ holds are tailored for 40-foot containers, anchored by vertical steel angle bars, or cell guides, ensuring precise positioning. These guides offer ample longitudinal and transverse support, negating the need for additional securing. Meanwhile, stacking 20-foot containers in 40-foot bays demands longitudinal and transverse reinforcement, achieved through mid-bay guides, stacking cones, and possibly overstowing. It’s vital to inspect guides for deformities before loading.

Typical Arrangements for containers stowed below deck:

1

CONTAINERS SECURED BY TWISTLOCKS. Usually for two tiers only.

2

CONTAINERS SECURED BY TWISTLOCKS AND LASHING RODS. Lashing rods to bottom of second tier. Wind lashings to bottom of third tier.

3

CONTAINERS SECURED BY TWISTLOCKS AND LASHING RODS. Lashing rods to bottom of third tier.

4

AS ABOVE BUT LASHINGS ORIGINATE FROM A LASHING BRIDGE. Lashing rods to bottom of fifth tier.